Magnetic Gorilla Guard Helps Construction Safety Engineers Address Swing Radius Hazards.

CONEXPO takes place in Las Vegas, NV every three years and boasts over 1,800 construction equipment manufacturers and exhibitors. ConExpo is also an event to learn about the equipment and technology transforming the construction industry.

CONEXPO takes place in Las Vegas, NV every three years and boasts over 1,800 construction equipment manufacturers and exhibitors. ConExpo is also an event to learn about the equipment and technology transforming the construction industry.

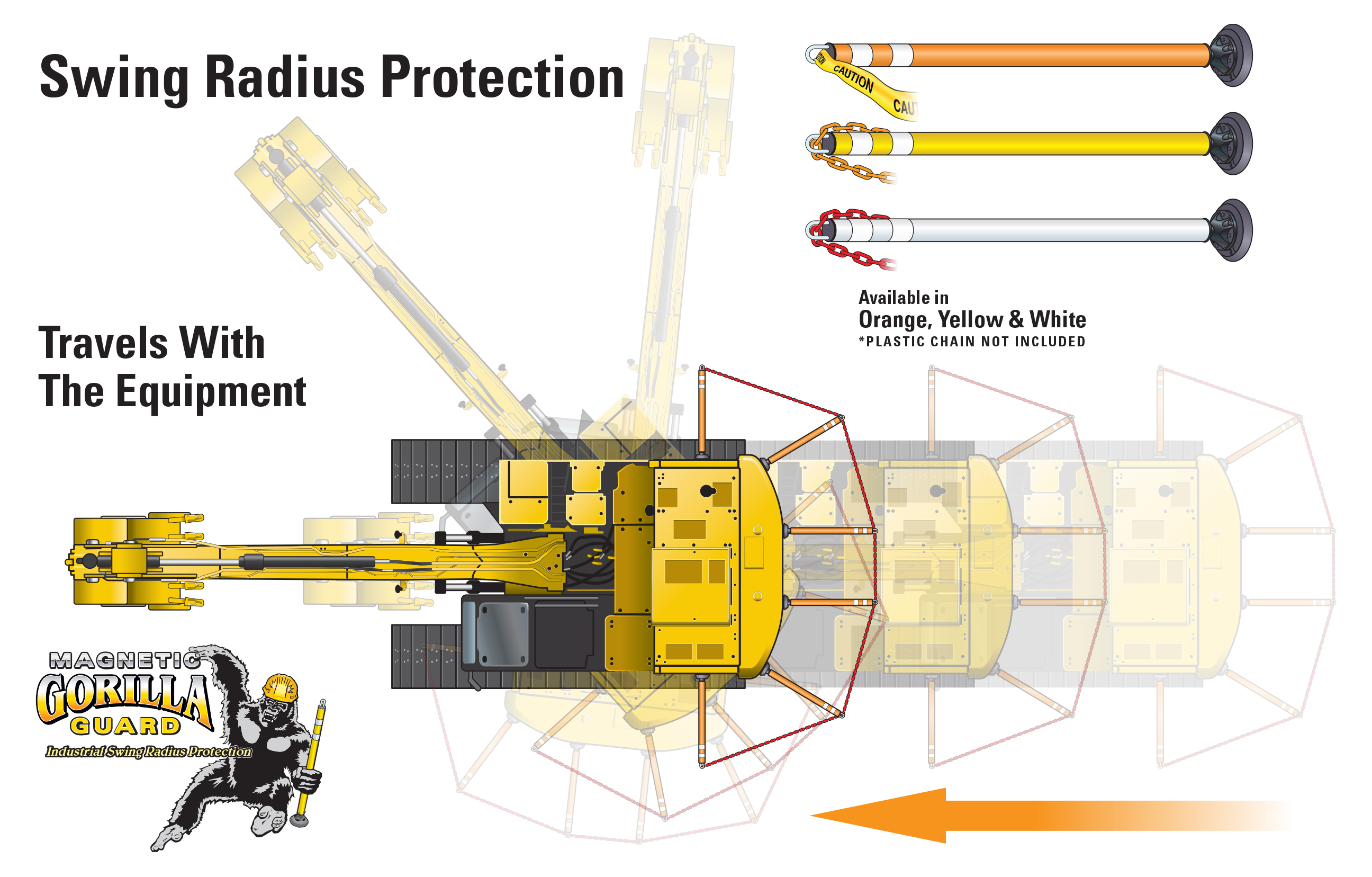

Part of the Gorilla Post Magnetic Mounting System, the Magnetic Gorilla Guard attaches to mobile heavy equipment to provide swing radius protection and warn co-workers of potential injury risk.

The Occupational Safety and Health Administration (OSHA) oversees and enforces standards for a safe working environment. OSHA has regulations regarding work area control around cranes and derricks addressing swing radius hazards. The requirements apply where there are accessible areas in which the equipment's rotating superstructure poses a reasonably foreseeable risk of striking or crushing an employee against a part of the equipment or another object.

Normally, construction companies must indicate the swing radius area by placing delineators or barricades on the ground around mobile equipment, so workers do not stand in, or approach the pinch point hazard areas. When the crane, excavator, or drill superstructure moves, the surrounding barricades need to be moved as well.

Normally, construction companies must indicate the swing radius area by placing delineators or barricades on the ground around mobile equipment, so workers do not stand in, or approach the pinch point hazard areas. When the crane, excavator, or drill superstructure moves, the surrounding barricades need to be moved as well.

Magnetic Gorilla Guards arrive assembled and are ready for deployment straight from the box. The guards magnetically mount directly onto the body of a crane or derrick creating a mobile swing radius solution within minutes. Once installed, the Magnetic Gorilla Guard eliminates the need to pause work for moving barricades around the equipment providing time and labor savings. Lightweight plastic chain, caution tape, or lightweight rope can be threaded through the loop cap at the top of the Gorilla Guards creating a continuous visual barrier around the equipment. Magnetic Gorilla Guards have a 360° pivoting spring base which is impact-resistant yet flexes if it hits an employee or object.

According to Bill Sloniker, WA State Dept. of L&I – Crane Certification Program Supervisor / Crane Technical Specialist, the Magnetic Gorilla Guard satisfies the WAC 296-155-53400 Requirements for work area control and swing radius hazards. When applied in the manner of the accompanying photos, the Gorilla Guards meet the standard for protection against pinch/crush hazards by the superstructure. In addition, employers must train their employees how to recognize the pinch/crush hazard areas.

Construction companies and operators should check local OSHA regulations for deployment placement, the quantity of Gorilla Guards needed, and how they are linked together.

Magnetic Gorilla Guard

Featured at ConExpo March 14 - 18, 2023

Booth #N13141

ParkingZone is proud to supply numerous industries with the best products available. Call us at 1-800-292-7275, chat with us from our website, or message us online if you have any questions about your needs and challenges. We are available from 8am to 5pm PST, Monday through Friday.